Heat recovery in heat pumps for domestic hot water (DHW) production

In light of the planned phase-out of fossil-fuel boilers set out in the new European Energy Performance of Buildings Directive (EPBD 2024), KEYTER is strengthening its commitment to heat pumps as a cornerstone of sustainable HVAC. The Spanish company has developed systems capable of harnessing waste heat for the production of domestic hot water (DHW) at zero additional energy cost, offering an efficient, regulation-compliant and environmentally aligned alternative that meets European requirements.

Quoting the exact wording of the EPBD 2024 (Energy Performance of Buildings Directive):

“Two thirds of the energy used for heating and cooling buildings still comes from fossil fuels. To decarbonise the building sector, the gradual phase-out of fossil fuels in heating and cooling is particularly important. Therefore, Member States should indicate in their national building renovation plans the national policies and measures to gradually phase out fossil fuels in heating and cooling. They should strive to phase out stand-alone boilers powered by fossil fuels and, as a first step, from 2025 they should not grant any financial incentive for the installation of stand-alone boilers powered by fossil fuels, except for those selected for investment before 2025 under the Recovery and Resilience Facility…”

Does this imply the disappearance of fossil-fuel boilers? Continuing with the quotes:

“Member States shall make efforts to replace stand-alone boilers powered by fossil fuels in existing buildings, in line with national plans for the gradual phase-out of fossil-fuel boilers.”

And in its Model for National Building Renovation Plans, it states:

“the decarbonisation of heating and cooling, including through district heating and cooling networks, and the gradual phase-out of fossil fuels in heating and cooling, with a view to the complete elimination of fossil-fuel boilers by no later than 2040.”

It seems that DHW production in buildings will fall to heat pumps, as indicated by the definition of a “Technical Building System: technical equipment of a building or building unit intended for space heating and cooling, ventilation, domestic hot water, built-in lighting, building automation and control, on-site renewable energy generation and energy storage, or a combination of these, including installations that use energy from renewable sources.”

Of the eight systems recognized by the EPBD 2024, four of the five that consume energy are handled by the heat pump.

In this context, KEYTER, as a Spanish manufacturer of HVAC&R solutions, has focused its efforts on developing heat pump–based technologies that can effectively replace fossil-fuel boilers in industrial, tertiary (commercial), and residential applications, anticipating the targets set by the European Directive.

But is it enough for the heat pump to be the main DHW generator? Let’s not forget renewable installations — among which the heat pump is included — such as solar thermal panels.

Definitely not. It isn’t enough. The heat pump can add a very important extra to DHW generation: producing it for free, with no energy cost and absolutely zero emissions.

Heat recovery for zero-energy-cost DHW production

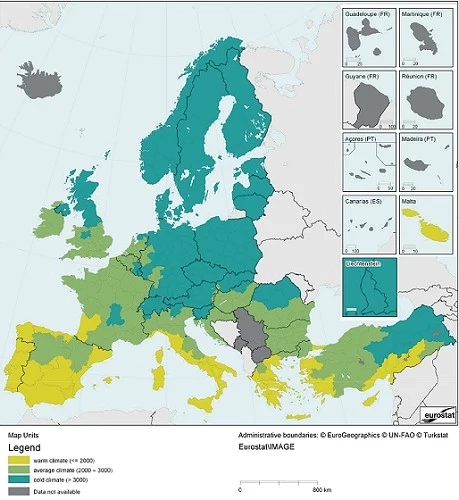

Anyone familiar with how a heat pump works knows that, in cooling mode, it releases to the air more energy than it produces for air conditioning, and that, normally in Average and Warm climates, in heating mode it is oversized, since the previous cooling load tends to dominate equipment selection. Therefore, a huge amount of energy is dissipated into the atmosphere without being utilized.

In line with the decarbonization strategy and the pursuit of high-efficiency solutions, KEYTER’s heat pumps integrate heat recovery systems designed to maximize energy utilization and reduce the carbon footprint of facilities.

KEYTER is particularly attuned to this issue, and in our Air-to-Water and Air-to-Air product ranges we offer a Hot Gas Waste Energy Recovery system as added value. This Waste Energy Recovery is based on using part or even 100% of the condensation energy—depending on the operating mode—to produce DHW free of charge.

The hot gases right at the compressor outlet are excellent for producing DHW: their temperature is very high, heat exchange with mains water is highly efficient… and they’re free.

We say they’re free because they’re produced using the energy the unit absorbs when operating in cooling mode—100% free. And if they’re produced while operating in heating mode, the concept of seasonal efficiency on primary energy guarantees an efficiency of around 200%, i.e., an estimated SCOP of about 4. The heat pump provides that “magic” of delivering usable energy with very low consumption.

But, as always, it must be done correctly at the Regulatory, Normative, and Technical levels, and with hybridization of technologies in mind:

The most common methods for its generation include:

- Heat pumps: Capture energy from outdoor air to heat water with high efficiency.

- Gas boilers: Operate by burning natural gas or LPG to heat water.

- Solar thermal panels: Use solar radiation to heat water, reducing conventional energy consumption.

- Electric systems: Electric resistances heat the water in storage tanks or instantaneous heaters.

From a regulatory standpoint, RITE and CTE are undoubtedly the fundamental pillars, and at the normative level, UNE EN 12831-3 serves as the main reference.

Standard UNE EN 12831-3

The UNE EN 12831-3 focuses on calculating the domestic hot water (DHW) thermal load, defining methods for estimating consumption and criteria for system sizing. Its key aspects include:

- Determining DHW demand: Based on the number of users, consumption habits, and required water temperatures.

- Thermal load calculation: Takes into account factors such as simultaneity of use, heat losses, and system efficiency.

- Sizing of storage and distribution systems: Includes criteria for storage volume, thermal insulation, and supply flow rates.

- Modules M8-2 and M8-3: Focus on characterizing demand and thermal load in DHW systems.

This standard applies to new-build and retrofit projects alike, ensuring an efficient design aligned with actual consumption needs.

Compared with other similar standards, it presents key differences in its approach and application:

- UNE EN 12831-3 vs. UNE EN 15316-3-1: The UNE EN 12831-3 replaces UNE EN 15316-3-1, improving the calculation methodology and adapting it to current energy efficiency requirements.

- UNE EN 12831-3 vs. Technical Building Code (CTE): While UNE EN 12831-3 provides a detailed method for calculating thermal load, the CTE establishes general requirements for energy efficiency and DHW demand in buildings.

- UNE EN 12831-3 vs. RITE: The Regulation on Thermal Installations in Buildings (RITE) incorporates UNE EN 12831-3 as a reference for sizing DHW systems, ensuring compliance in HVAC project design.

In general, UNE EN 12831-3 is a specific technical standard that complements broader regulations such as the CTE and RITE, providing precise tools for the efficient design of DHW systems.

UNE EN 12831-3 and the EPBD (Energy Performance of Buildings Directive) are related within the field of building energy efficiency, but they have different focuses.

UNE EN 12831-3 complements the EPBD by providing technical tools for the precise calculation of DHW thermal demand within the energy-efficiency framework required by the European directive.

At KEYTER, our units and control systems are designed in line with the sizing and efficiency principles defined by this standard, ensuring that every DHW installation optimizes its performance according to real operating conditions.

Integration of advanced technology and sustainability

At KEYTER, our commitment to sustainability and energy efficiency is reflected in our range of heat pumps for DHW production. Using propane as the refrigerant, these advanced solutions not only comply with the most stringent regulations, such as RITE, but also significantly reduce environmental impact by using low-GWP refrigerants.

Energy efficiency with propane

KEYTER’s heat pumps using the natural refrigerant R290 (propane) represent a key technological evolution in sustainable DHW production, combining the best of technology with a responsible approach to the environment. Their high energy efficiency and low consumption enable more economical use of resources, resulting in a notable reduction in CO₂ emissions and substantial savings for users.

Flexible and adaptable solutions

Designed to adapt to different types of installations, they are ideal for residential, commercial, and industrial applications, providing domestic hot water (DHW) efficiently and sustainably. The ability to integrate these units with other renewable technologies—such as solar panels—offers a perfect hybrid solution to optimize system performance and maximize energy savings.

Regulatory compliance and technological advances

Through our equipment, we not only meet the requirements set by UNE EN 12831-3 and RITE, but also deliver solutions that add real value to decarbonization projects. Our propane heat pumps achieve top efficiency in DHW production, ensuring stable, reliable performance throughout their service life.

A step forward toward a sustainable future

KEYTER is committed to a greener, more efficient future. The deployment of our propane heat pumps in domestic hot water (DHW) systems is a clear example of how technological solutions can transform the HVAC&R industry, contributing to decarbonization effectively and with a positive environmental impact. With solutions designed and manufactured entirely in Spain, KEYTER is consolidating its position as a leader in the transition toward cleaner, more efficient, and environmentally responsible climate control.

More articles

Interested in other (technical) knowledge articles? Keep yourself up to date and read them all