To realize an optimized air-cooled heat pump, Keyter Intarcon Nederland B.V., Keyter Technologies, S.L. and the Danish partner Klimalux have shared their knowledge and put their hand together. The result is an inventive heat pump that performs good at temperatures around 0°C with relative high humidity, but also at very low outside temperatures (around -20°C).

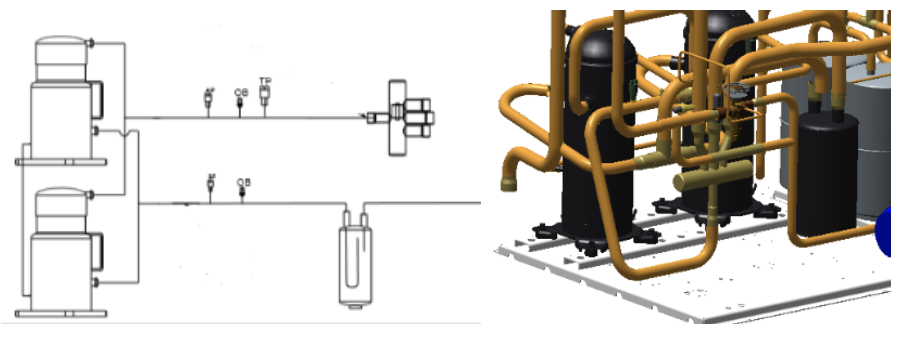

The idea of this development started when governments in most of the northern part of Europe (The Netherlands and Scandinavia) obliged companies to build gas-free. The developed Keyter KWK heat pump has put real emphasis on heating during design and development. There is not only a four-way reversing valve and neither a defrost cycle added to the standard chiller. But it also anticipates on the strict laws in these countries in order to attempt to keep refrigerant content of the individual refrigerant circuits circuits as small and short as possible. Fior example, most of these KWK units meet the Scandinavian requirements of 10 kg max. per circuit.